What is a membrane structure

Membrane structure is a new building structure developed a kind of form, it is material with excellent performance of the fabric, or to the membrane aeration, membrane supported by air pressure, or the use of flexible wire or rigid support structure onto the surface, forming a certain stiffness, can cover large span space structure of the system.

Membrane structure story

Clearance size in Osaka, Japan in 1970 world's fair is 140 m by 83.5 m of the USA pavilion is a membrane structure of large span, since then, membrane structure in foreign countries has been gradually applied to sports buildings, shopping malls, exhibition center, transport facilities, such as the construction of large span, membrane structure in the world scope got rapid development.

Built in the United States in 1975 Mr Ark "silver dome" gas bearing type air, membrane structure, plane size 234.9 m by 183 m; Jida 1981 Saudi Arabia airport lounge suspension membrane structure, covers an area of 420000 m squared;

The 1988 Olympic Games in Seoul, gym and fencing hall; 2000 London "dome" in one thousand, with its unique design of membrane structure model and advance shows the membrane structure architecture technology and the development of materials science.

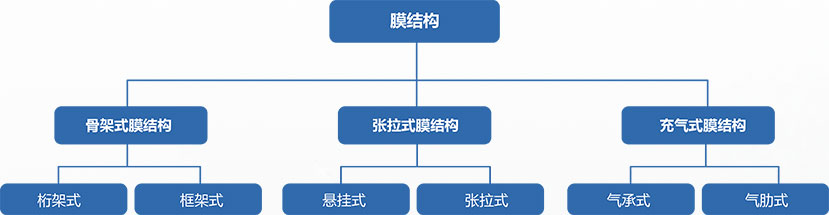

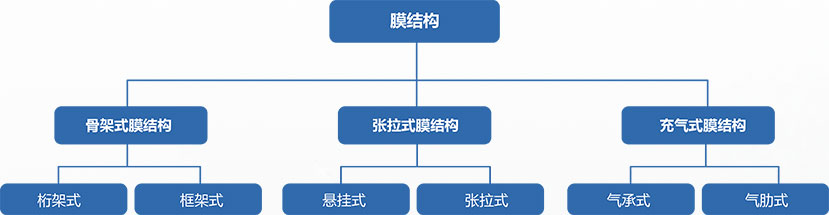

Membrane structure framing

"Made up of steel structure and other integrated timber roof skeleton, tensioned membrane material on top of the structure of the form.

Low characteristics: because of the design is simple, the advantages of good mechanical performance, strong practicability, and is quite popular with designers.

Application: low in sports venues, sports stadium, exhibition center, airport terminal, the station waiting room, toll station, bike shed, and other fields are widely used.

Type of tensioned membrane structure

Low membrane materials, wire and steel structure pillars, through wire, pillar and tension stress balance between membrane material structure in order to achieve a stable form.

Low features: large space, large span and light weight is the characteristic of this structure. Besides, innovative, progressive, beautiful modelling, also show the structure of the membrane structure. Charm forms. In recent years, the large span space also used more to wire and bar space in the form of wire mesh to support the upper membrane material. General design by span larger, less dosage of steel structure, but the quality of membrane material demand is higher, need to use high strength of membrane material, also because there is no limit to the modelling of frame structure, membrane structure smooth, elegant, beautiful shape.

Low application: widely used in large sports venues, square landscape, coastal landscape, outdoor stage, swimming pool, etc.

Inflatable membrane structure

Inflatable membrane structure, appellation pneumatic membrane structure again, confined space, intelligent configuration and mechanical and electrical control system, to support the whole building by pressure difference inside and outside.

Low characteristics: can be set in any climate, environment, geographic conditions, because of the flexibility of the material and structure and effectiveness of the inherent arc shape, without bending, torsion and compression artifacts, internal without any frame or beam support, span 200 meters.

Low application: widely used for indoor sports stadiums, basketball courts, badminton courts, football, swimming pool, etc.) as well as coal, mine, need to seal, such as the pollution soil of large structures.

Membrane material performance

Optical performance

Membrane materials can filter out most of the ultraviolet ray, prevent the internal objects fade. Its transmissivity of natural light is ranged from 15% to 95%, the transmitted light evenly diffuse light inside the structure, no shadow, no glare, good color rendering, night in ambient light and interior lighting, under the joint action of membrane structure on the surface of natural soft glow, intoxicating.

Self-cleaning performance

Material of membrane surface did not sticky layer processing, has the very good self-cleaning properties, rainy days, the dust on the surface of the membrane material will be under the rain washed out, get down into the water, get natural cleaning surface of membrane material.

Acoustic performance

General membrane structure for less than 60 hz low frequency is almost transparent, for there is a requirement for special sound-absorbing structure can increase the FBA (FABRASORB) lining, this combination was stronger than glass with sound-absorbing effect.

Heat preservation performance

Heat preservation performance is the same as the brick wall single-layer membrane material, is better than that of glass. For a membrane structure with high insulation requirements, can be achieved by increasing the lining insulation heat preservation and heat insulation performance of excellence.

Fireproof performance

Now widely used membrane materials can well meet the demand for fire prevention, flame retardant and high temperature resistant performance, to France, Germany, the United States, Japan and other international standards.

Mechanical properties of

Medium strength of PVC film, the thickness is only 0.8 mm, but its tensile strength is equal to half of the steel. Medium strength of PTFE membrane, its thickness is only 1.0 mm, but its tensile strength has reached the level of steel. Membrane material of elastic modulus is low, it is advantageous to the membrane material to form complex surface modeling.

Membrane material is introduced

Membrane material is a kind of new building materials, has been widely recognised as the brick, stone, concrete, steel and wood after "6 kinds of building materials". Refers to polyester fiber or glass fiber membrane materials for the base fabric with different surface coating, can withstand a certain load construction textiles. Usually with PVDF, TIO2, PTFE, ETFE membrane materials, etc.

ETFE materials

ETFE is Ethylene (PVC), Tetra (4), Flour (CFC), Ethylene (PVC) four English abbreviations. ETFE materials without any cloth, only four fluorine by a layer of PVC (PVC film, PVC fluorine PVC itself has the very good chemical stability, do not need any other surface protection. Life in more than 30 years, has the very good self-cleaning, refractory, light transmittance about 95%.

1, good durability: adaptation: - 200 ~ 150 degrees Celsius, more than 15 years of bad weather, mechanical and optical properties do not change.

2, high tensile strength, breaking elongation rate of more than 300%.

3, high security: flame retardant materials, contraction after fusion without dripping.

4, ETFE membrane surface is smooth, almost without daily maintenance, since the high noise, dust dirt wash it with water.

5, light structure, good shock resistance, convenient installation.

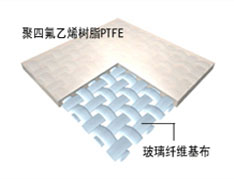

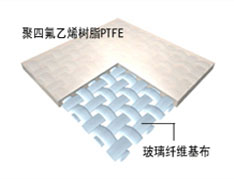

PTFE membrane material

PTFE membrane materials refers to the very fine glass fiber woven mu (3 m) on the base fabric of coated PTFE (polytetrafluoroethylene) resin to form a composite material.

1, PTFE membrane material has high strength, good durability, fire flame retardant, good self-cleaning function, etc.

2, PTFE membrane material of the light from the sun with a high reflectivity and low absorption rate, can save energy costs.

3 free, PTFE membrane structure building design, the use of diversity

4, PTFE with PVDF incomparable high self-cleaning, appearance the accumulation of atmospheric dust, dirt, etc in the rains washed out after being dry cleaning

5, fire prevention materials, high safety, and long service life, more than 30 years.

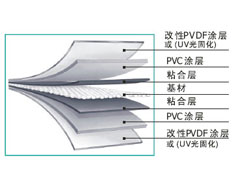

Membrane material in environmental engi✱neering

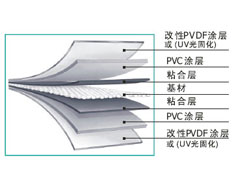

1, unique modified PVDF coating

On PVDF coating added special modified additives, can not only improve the self-cleaning properties of membrane material can directly welded again, at the same time, the modified additives and additive synergism in the PVC layer, make the combination of PVDF and PVC coating more strong, not easy to peel, no longer need to coating base layer.

2, UV light curing processing

Advanced UV light curing processing technology, which greatly improved the material in the strong corrosion, strong acid and alkali, salt spray, etc. The service life of the harsh conditions.

3, excellent antibacterial, mouldproof

Coating surface increased corrosion, acid and alkali treatment, prolong the service life of membrane material under the special environment, increase the membrane material closure.

Membrane material comparison table

|

indicators

|

ETFE materials

|

PTFE membrane material

|

PVDF membrane material

|

Membrane material in environmental engineering

|

Acrylic membrane material

|

|

Using the environment

|

To demand higher buildings, such as terminal, waiting area, etc

|

To demand higher buildings, such as terminal, sports venues, etc

|

The structure with not high requirements, or special requirements of buildings, such as gas film

|

Sewage pool, pollution soil sealing

|

Out products

|

|

The base cloth material

|

Four fluorine PVC PVC

|

The glass fiber

|

Polyester (PVC)

|

Polyester (PVC)

|

Polyester (PVC)

|

|

The surface coating

|

There is no

|

PTFE coating

|

PVDF coating

|

Aging proof corrosion resistant coati🤡ng

|

acrylic

|

|

Self-cleaning function

|

Very good

|

Very good

|

good

|

good

|

poor

|

|

Light transmittance

|

95%

|

6-15%

|

5-20%

|

5-15%

|

5-20%

|

|

The service life of the

|

More than 20 years

|

More than 30 years

|

15 to 25 years

|

15 to 25 years

|

3 to 5 years

|

|

The tensile strength

|

N. 1000-1000

|

N. 4000-4000

|

N. 3000-3000

|

N. 3000-8000

|

N. 3000-8000

|

|

Fire rating

|

B1

|

A2

|

B1

|

B1

|

B1

|

|

The mode of transportation

|

The mode of transportation

|

The mode of transportation

|

folding

|

folding

|

folding

|

|

The processing difficulty

|

difficult

|

difficult

|

easy

|

easy

|

easy

|

|

installation

|

Air pillow

|

Second tensioning type

|

A tension

|

A tension

|

A tension

|

|

The price

|

higher

|

high

|

general

|

general

|

PVDF 10-20%

|

Membrane structure maintenance membrane structure maintenance inspection

Regularly check whether the membrane structure is under normal working condition.

Inspection mainly covers the membrane material for large deformation, membrane material is due to the loss of pretension is flabby, partially torn whether membrane material, membrane material coating whether stripping, cable is loose, the paint is peeling off, etc.

If the above problems, please inform us send professional and technical personnel for maintenance.

Membrane structure maintenance inspection

Membrane material maintenance

1. Project delivery after use, the owner does not change the structure, shall not remove any bolts artifacts, such as the need to change, please contact our company through stress evaluation rear can change;

2. Steel structure components should paint to maintenance once a year, to extend the steel structure housing overall appearance and extend the use fixed number of year;

3. The owner decorate electric lighting equipment, wire and not directly binding on steel members, shall be installed slot line pipe or isolation, lest produce an electric shock.

4. Clean surface of steel structure are out of scratching phenomenon, avoid using bleach ingredients and abrasive containing acid liquid to wash, washing supplies, steel wire ball, wear-resistant products are not allowed to use, rinse with clean water from top to bottom.

1, the regular of not less than 3 times a year check and clean the leaves on the surface of the membrane structure roof and piled up sundry, especially in the wake of typhoon;

2, the structure of the membrane surface can be here, but you can't have sharp objects contact surface of membrane material, also can't wear shoes to walk on the surface of the membrane material, to prevent wear protective layer on the surface of the membrane material;

3, no less than once a year in the cleaning surface of membrane material, it is strictly prohibited to use strong detergent, such as the days that water, appropriate use of relatively mild detergent or diluted cleaning detergent and so on, at the same time, it is forbidden to use steel brush surface cleaning, appropriate USES plastic brush or cloth for cleaning, avoid damage the surface of membrane material;

4, membrane material belongs to non-combustible objects, but the flame will be melt, so should be avoided in the membrane material has the high temperature objects such as fireworks, welding;

5, membrane material has certain elasticity and tension strength, but should avoid falling objects fall on the membrane surface, especially the sharp glass, iron, stone, brick, etc.;

6, membrane material surface has become very slippery after water, in the above operations necessary to strictly pay attention to safety, buckle the safety belt, safety protection measures;

1. Project delivery after use, the owner does not change the structure, shall not remove any bolts artifacts, such as the need to change, please contact our company through stress evaluation rear can change;

2. Steel structure components should paint to maintenance once a year, to extend the steel structure housing overall appearance and extend the use fixed number of year;

3. The owner decorate electric lighting equipment, wire and not directly binding on steel members, shall be installed slot line pipe or isolation, lest produce an electric shock.

4. Clean surface of steel structure are out of scratching phenomenon, avoid using bleach ingredients and abrasive containing acid liquid to wash, washing supplies, steel wire ball, wear-resistant products are not allowed to use, rinse with clean water from top to bottom.